Why the 3,000-Mile Truck Oil-Change Rule Is a Myth

The idea that you must change your vehicle’s oil every 3,000 miles is deeply ingrained in automotive culture. For decades, many fleet managers and owner-operators followed the “3k rule” as a safe default for a truck oil change. However, today’s vehicles, lubricants, and maintenance technologies have advanced, making that rigid interval outdated.

Simply put, you don’t always need to change your oil at 3,000 miles.

In this guide, we explore how the 3,000-mile interval arose, how engine and oil technology have shifted, and how modern guidelines and monitoring systems can determine intervals more precisely.

Origins of the 3,000-Mile Interval and the Emergence of Synthetic Oils

The 3,000-mile oil-change rule took hold in the 1960s and 1970s, when most vehicles relied on conventional mineral-based oils. These early lubricants broke down quickly under heat, oxidation, and contamination. Engines of the time were less precise in their machining and used materials that generated more wear particles. Combined with shorter trips and less effective filtration, oil simply didn’t last as long as it does today.

Service shops began promoting the 3,000-mile interval as a safe, easy-to-remember standard. It became a mantra of preventive maintenance: better to change too soon than risk engine damage. For many years, that advice made sense. Oil chemistry was limited, and the cost of frequent truck oil changes was small compared to the potential cost of engine failure.

Then, synthetic oils entered the picture. Developed with advanced refining and chemical processes, these lubricants offered higher resistance to heat, oxidation, and sludge

formation. They maintained their viscosity longer, flowed more easily in cold conditions, and reduced internal engine friction.

As synthetic oils became more common, the old 3,000-mile benchmark started to lose its relevance. These new formulations could easily go 7,500 or even 10,000 miles before degrading, especially in engines built to take advantage of their properties.

How Engine and Oil Technology Changed Maintenance Cycles

Modern engines and oils have transformed what a proper oil change interval looks like, especially for commercial trucks. Consider the following improvements:

Engine designs now routinely use lighter alloys, variable geometry turbochargers, direct fuel injection, and advanced emissions equipment. These changes place different demands on oil but are also more robust.- Oil formulations are now much more advanced: improved synthetic blends, full synthetic oils, enhanced additive packages, and better detergency. These support longer service intervals.

- Filtration systems have improved to include deeper capacity, finer media, and often more effective bypass filtration in heavy-duty applications.

- Engine monitoring and diagnostics are now more sophisticated. Sensors monitoring crankcase pressure, oil condition, and temperature/humidity, as well as onboard telematics systems, can detect when a truck oil change is truly needed rather than relying on an arbitrary interval.

These changes mean that a one-size-fits-all interval such as “every 3,000 miles” is no longer necessary, or optimal, for many modern trucks. Instead, the interval should reflect vehicle design, duty cycle, oil quality, and operating conditions.

Using OEM Guidelines and Oil Monitoring Systems

To determine a proper truck oil change interval, two major pillars stand out:

1. OEM (original equipment manufacturer) guidelines.

Manufacturers publish service intervals in the owner’s manual or service materials. These intervals are determined based on engine design, oil type, operating environment, and warranty considerations. For heavy-duty trucks, the OEM might recommend intervals of tens of thousands of miles or more under normal service. Following the OEM guideline is a far better baseline than reverting to the generic 3,000-mile rule.

2. Oil condition monitoring systems.

Many fleets and modern vehicles now include sensors and telematics to track oil quality, contamination, degradation, and usage. These systems can:

Measure oil oxidation or nitration levels.- Monitor soot or particulate loading in the oil.

- Track actual operating hours, engine starts, idle time, load cycles, and ambient conditions, all of which affect oil condition.

- Alert when oil parameters exceed safe thresholds, prompting a change.

Using these tools allows truck operators to shift from time- or distance-based intervals to condition-based schedules. A truck might run far more than 3,000 miles between oil changes, or it might require an earlier change if it’s doing heavy stop-start loads, extreme temperatures, or high idling hours.

Beyond Onboard Sensors: The Value of Oil Analysis

For the most precise condition-based maintenance, many fleets and owner-operators rely on regular oil analysis. This process involves taking a small sample of used oil and sending it to a laboratory. The resulting report is a detailed health check for the oil and the engine. It reveals the oil’s remaining viscosity, additive levels, and any contaminants such as soot, fuel, or coolant. Critically, it also measures the presence of specific wear metals, like iron, copper,

or lead.

This information not only pinpoints the exact moment the oil needs changing but also serves as an early warning system for internal engine problems, like a failing bearing or a coolant leak, long before a catastrophic failure.

Why Dumping Oil Prematurely Is a Cost and Environmental Drain

Changing oil too early is more than unnecessary maintenance; it has real cost and sustainability implications.

Cost implications:

Frequent truck oil changes increase parts and labor costs.- Premature disposal of serviceable oil reduces return on investment for that fluid.

- For fleets, unnecessary downtime for oil service reduces productivity and raises the total cost of ownership.

Environmental impacts:

Used oil must be collected, processed, or disposed of safely. More frequent changes increase the volume of used oil waste.- New oil manufacturing, packaging, and shipping also carry environmental costs (energy, raw materials, logistics).

- By optimizing oil change intervals, you reduce waste and environmental footprint, while still preserving engine integrity.

In short, if the oil is still performing and protecting the engine, changing it simply because 3,000 miles passed might be wasteful. That doesn’t mean skipping truck oil changes entirely; it means basing them on condition rather than tradition.

How to Determine Modern Truck Oil-Change Intervals

Here are actionable practices to determine and manage oil-change intervals for modern trucks:

1. Start with the OEM interval.

Refer to the truck manufacturer’s service manual. Note whether the interval applies under normal or severe service conditions. Many heavy-duty trucks have service intervals of 15,000 to 25,000 miles or more for oil changes under recommended oil and filter types.

2. Understand your duty cycle.

Heavy idling, short trips, frequent stops, extreme loads, high ambient temperatures, and unclean environments all shorten oil lifespan. If your vehicle operates under severe duty conditions, consider shortening the interval or rely more heavily on condition-based monitoring.

3. Use condition-monitoring tools.

Install oil sensors or use telematics to measure oil degradation, soot loading, and operating parameters. If sensors indicate oil health is declining, change early; if oil remains healthy beyond the standard interval, you may safely extend it.

4. Choose the right oil and filter.

Use high-quality synthetic or synthetic-blend oils specified by the manufacturer, as well as filters with proven efficiency and capacity. The combination will help extend oil life and protect the engine over longer intervals.

5. Track engine hours along with mileage.

Mileage matters, but engine hours and idle time often matter more in commercial truck use. A truck that does many idle hours may degrade oil faster than one that racks up miles at highway speed.

6. Maintain clean engine air and crankcase systems.

Keeping air intake systems clean, ensuring crankcase ventilation is functioning, and maintaining cooling systems helps the oil last longer and stay cleaner.

7. Track and analyze the performance.

Keep records of oil condition, hours/mileage at oil change, and any abnormal operating conditions. Over time, you’ll build a data-driven profile of what interval works well for your fleet or individual truck.

By moving away from the blanket 3,000-mile interval and toward a data-driven, condition-based schedule, you will maximize engine protection, reduce unnecessary maintenance, and optimize total cost of ownership.

Real-World Considerations for Fleet Managers and Owner-Operators

Here are specific tips for those scheduling truck oil changes:

Segment your trucks by duty cycle. Highway-only trucks may stretch intervals further than regional trucks with stop-start service.- Use telematics to track actual idle hours and load conditions, then compare with oil lab data or sensor readings.

- Budget maintenance based on condition rather than calendar-based service work.

- Communicate to drivers: let them know why longer intervals are possible when oil remains good, but emphasize that monitoring is the key; not simply “I’ll wait until 10,000 miles because someone told me that’s okay.”

If you adopt this approach, you will protect your engine health, streamline maintenance planning, and reduce idle time and costs.

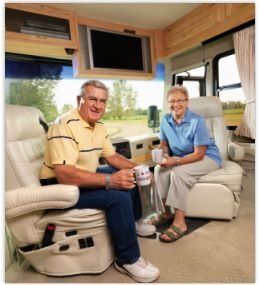

Contact Mainline RV & Truck Service for Your Truck Oil Change

If you’re looking for a reliable partner for your next truck oil change, turn to

Mainline RV & Truck Service in Cleveland, Ohio. We have the experience and diagnostic capabilities to determine the right service interval for your individual truck or fleet. Call 440-439-7777 or fill out our

online contact form to schedule your oil change today.